|

Metalworking Comments |

|

|

| I have

a mini-mill, the small one imported by Grizzly. I havenít modified it yet,

except by adding a light. Iíve got an idea for another accessory, so Iíll

put that in. Somewhere in here I have a power hacksaw (no mods, yet) and an

arbor press that Iíll modify for terminal staking. |

| First:

some comments on the lathe; I used to have a Unimat lathe, and everything

on it was adjustable. Since it was designed to be a combination

mill/drill/lathe, the entire headstock was mounted to be removed, put on a

post, and oriented vertically for milling and drilling. It did all these

things, but needed constant tending. It was also a little too small for some

of my projects, and had great difficulty in turning anything larger than

about an inch and a quarter. Iíd not been kind to it over the years, but the

major problem was that I could not find any belts locally. Now I know that I

can find them over the internet, but I thought it was time to move up.

Thereís a Harbor Freight store near me, and while I shuddered at the fit

and finish on some of the tools, the 7 x 10 was a possibility, because it

didnít look TOO bad! A search of several sites gave me some very good ideas

of the quality and problems with it, and I decided to take the plunge. That

it was on sale for $50.00 off, well, that didnít hurt.

Pictures and comments are next.

|

|

Does anybody else have a two

tone lathe? This one is yellow and red. |

|

The 3 jaw chuck looks to be the

best piece in the whole design. Inside jaws are shown. |

|

Overall, this isnít bad for fit and finish. It looks like some of the parts

were sand cast, because the finish seems almost rough in places. However,

the parts that need to be finished are, and thatís probably good enough.

What this isnít, is a coherent part of an entire machine shop setup.

You canít get all the accessories you might want, and thatís a problem. |

|

Plusses: Available,

got to see before I bought. Larger and more rugged than Unimat. Thread

cutting. Variable speed, minimal numbers of belts. Much more like an

industrial lathe. Minuses: Needs work on fit and finish, some adjustments

will be needed. Leaning over control panel can throw lathe into reverse.

Threading needs gear changes. Manual is rather sparse. 5/16 inch tools,

while standard, are more difficult to find. This is what youíd get if you

bought Craftsman, I think, and Iím not buying Craftsman very much at all.

Would I buy it again?

Yes, so far. Itís much better than I had, itís worth the money. I think

that if I continue to work with metal, Iíll probably get a larger lathe, but

thatís down the road. This is portable, easy enough to lift and carry away,

and will be of good use.

So far, itís been fun.

|

|

|

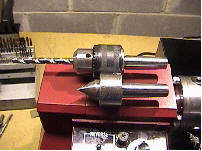

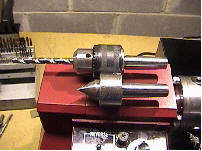

One of the first modifications I

did to the lathe was to cut the (not included) drill chuckís Morse Taper to

a suitable length. I cut it to the same length as the live center. I used a

radial arm saw with an abrasive blade, and cut down by sixteenths each time.

I then ground the end to smooth it, and belt sanded a small bevel on the

edge.

|

|

This shows the steps needed to

use a 1/4 inch tool on a lathe designed for 5/16 inch tools. I may fix this

to allow 3/8 inch tools. For that, Iíll need a 4 jaw chuck, and I think Iíll

just buy another toolpost. Itís only about 10 dollars or so. That way, I

donít mess things up. |

|

The thread dial arrived

vertically attached. There was not a connection between it and the lead

screw. Needless to say, the dial did not turn. Nowhere in the manual does

this get mentioned. I finally saw the connection and decided to tilt it

slightly so the gears matched. Now it works.

|